Oakshire Brewing’s Guide to Smoothie Sours

Guest post: Oakshire Brewing’s director of brewing operations Dan Russo on the trials and tribulations of smoothie sour beers.

By Dan Russo -

Since Ken Grossman brewed his first batch of Sierra Nevada Stout (predating the first batches of Pale Ale), there have always been polarizing opinions within the beer community about up-and-coming beer styles. As craft continued to transform from a corner niche market into full-blown mainstream, beer internet forums began to become flooded with old-school drinkers, first time consumers, homebrewers and hard-core beer geeks. Everyone had a place to make their opinion known, and known it was. In all that time, there has not been a more polarizing decade in beer than the 2010s, and it continues into 2021 with the fight over smoothie sour beer.

What is a Smoothie Sour Beer?

Smoothie sour beers (also known as pastry sours) are the evolution of the fruited kettle soured beers (such as Gose and Berliner Weisse) that made a resurgence and grew incredibly popular in the early part of the 2010s. Around the same time, brewers began to add non-traditional ingredients to traditional-styles in an attempt to recreate baked goods and desserts in liquid form. This all came to a head in 2015 when Pennsylvania’s Tired Hands Brewing and Sweden’s Omnipollo Brewing teamed up to create the first “Milkshake” IPAs using large amounts of fruit, vanilla beans, milk sugar (lactose) and spices along with a ton of hops; from there the smoothie craze was born. Eventually, brewers began to drift to other styles—specifically kettle soured beer—as the new vehicle to explore these wild and crazy fruit and adjunct combinations.

At their essence, when talking about any type of smoothie or milkshake beer, the common denominator is always extremely large amounts of unfermented fruit puree. By leaving the fruit unfermented, the brewer is essentially trying to make a beer that looks, smells, and drinks like a fruit smoothie from a juice café, but with alcohol. After that is achieved, there is a never ending list of adjuncts and spices that can be added to create whatever flavor a brewer wants. As the craze continues to grow, it is continually amazing to see the types of ingredients brewers are adding to beer in pursuit of experimentation. Sometimes they turn out great and other times they end up a big miss; the ones doing it right are truly pushing the bounds of flavor.

Oakshire and Smoothie Sour Beer

I’ve always been curious when new styles enter the fray of existence within craft. I think new is good, especially for small breweries with good direct-to-consumer bases. That being said, we always play it cautious when new and cool beers styles make their way to the forefront. We want to see how people are doing them, why people like them, try recognized examples of the styles, and formulate a plan on how we would improve upon them in our own way.

Smoothie Sours had been on a nearly two-and-a-half-year meteoric rise, similar to hazy and milkshake IPAs, before we decided to throw our hat in the ring. In late June of last year, we introduced “Theme From The Bottom - Triple Berry Smoothie Sour.” Our initial hesitation in tackling the style came from many different angles. We wanted to ensure that we understood what was expected of the style; the good and the bad; how to make the beers stand out as unique in a growing landscape; and how, to the best of our ability, to prevent refermentation and exploding cans, as well as consumer and company response to those issues (more on this later).

We had transitioned to releasing all of our pilot beers in 16oz cans at the beginning of June, and made Theme our second can release of the month. We made 80-6/4/16oz cases as well as draft, and put it on sale on a Thursday for $23 per 4-pack. We were clear out of all 80 cases within one week of release, and our social media was blowing up asking when we would be making new versions. So began our rabbit hole journey into creating new and exciting smoothie beer flavors!

How Our Smoothie Sours Are Made - Step by Step

We start with a grain bill that reads very similar to our core Hazy IPA recipe. The goal for us is to build a base beer that has a lot of body to stand up to the acid from the souring and fruit as well as provide a great base for any other additions that we may be adding later in maturation. We’re also shooting to make this an imperial sour beer as we will later be essentially diluting the beer with unfermented fruit puree. Our target OG is 23-24P (1.096-1.101 SG). We’re shooting for between 9.75% and 10.5% ABV (Depending on the FG being between 5P and 6P (1.020 -1.024)).

Our grist bill reads as follows. Note the grist bill in itself will not hit the desired gravity. We add dextrose during the boil.

2-Row 55%

Malted White Wheat- 14%

Carafoam or Dextrin Malt- 7%

Acidulted Malt-3%

Rolled Oats-12%

Dextrose (Boil)-9%

We mash low, between 148 and 149. Between the high gravity and the low pH of the sour wort, the low conversion point creates easy fermentable sugar and helps achieve the desired FG even as the yeast starts to struggle towards the end of fermentation. Mash salts include Calcium Sulfate (Gypsum) and Calcium Chloride, Food grade Phosphoric acid is used for mash pH adjustment

Souring

We have a sour tank (Lactobacillus Reaction Vessel) that has housed our house culture since 2016. The culture started from Nancy’s Yogurt back in 2015 and has evolved since. We knock out into our souring tank at between 125F and 130F (approx. 51-55C). We sour for approx. 18 hrs. In that time our culture generally reaches between 3.4 and 3.55pH, which is our desired range. We feel that keeping the pH above 3.4 allows for a much more balanced interaction with the acidity provided by the large amounts of fruit added during maturation. Starting with a pH lower than 3.4 can take a pleasant, fun and drinkable beverage to unpalatable and unpleasantly sour very quickly. After we hit our sour range, we send the wort back to the kettle for a short 40-minute boil. Kettle additions are nothing more than Yeast Nutrient, Whirlfloc and the Dextrose. No hops and no flavoring. Nothing to interfere with the adjunct additions down the line.

Fermentation

When we started this adventure, and with a hazy-style grist bill, the natural inclination was to use our favorite hazy yeast (Imperial Juice aka London Ale III). We came to realize that it struggled, pretty immensely, with the high gravity and pH to hit our targets. After a few batches we switched to our house strain (Imperial Flagship aka California Ale). For us it rips through the gravity and pH and gets us to the alcohol range that we are looking for. Fermentation goes at 67 degrees and hits terminal gravity in 9-10 days. We don’t cool or crash the beer before transferring to secondary. We drop whatever yeast that has settled before moving the beer.

Secondary Conditioning on Marshmallow Creme, Vanilla, and other Adjuncts(not fruit).

All of our Themes have one common trait: the addition of Marshmallow Crème (aka Fluff) and vanilla beans. This does not make the beers vegan, but adds a lot of depth with the fruit. The reason for a secondary conditioning before the fruit addition is two-fold. 1. Without the fruit, the base beer is allowed to interact with the other adjuncts, picking up flavor that will carry over into the finished beer without interference for the large amount of fruit. 2. We only condition and carbonate on the fruit for about 24hrs before packaging to impede the fruit from being able to settle and stratify in the brite tank. That’s not enough time to get any flavor from the additional adjuncts. We think those flavors get lost when directly mixed with fruit.

We use 3 lbs. of vanilla beans and 100 lbs. of marshmallow crème for each finished 14-barrel batch (including fruit additions). Other adjuncts that have been added during this stage include cinnamon, coconut and graham cracker. Our usual contact time is 5-7 days in secondary. Two days before the anticipated transfer we crash the beer and add Biofine to drop the remaining yeast in the tank and dumping it before we send it over to the brite tank with fruit.

Fruit additions, carbonation, and recirculation prior to packaging.

We’re adding fruit at approximately 40% of the finished volume of beer (about 6-6.5-barrels or 1500-1700 lbs.). We mostly use Oregon Fruit Products, as it is aseptic. Prior to addition, the fruit is stored in our walk-in cooler, otherwise the mixture will be close to 50F and near impossible to carbonate. The fruit is added into our conditioning tanks through a brink with CO2 under a closed system. After the fruit is added, we transfer the beer from cone to cone (getting as much of the beer as possible and mixing it with the fruit upon transfer). Once transfer is complete, we begin carbonation. Carbonation is all by feel, as the beer is too thick to get an accurate CO2 reading using our Zahm and Nagel CO2 Volume Meter (and instrument to measure CO2 in solution and help us get to the desired level of carbonation). It’s literally based on mouthfeel and how it cascades out of the zwickel. If I had to put a number on it, I believe we hit approx. 2.6 volumes of CO2 with our carbonation, but it’s all guess. But what you will learn is that even if it is “over-carbonated,” you won’t have hardly any issue with packaging. The beer is so thick that breakout is incredibly slow at the packaging line.

Once carbonation is at our preferred level we set up a variable drive pump from the bottom port to an upward pointed racking arm and begin a slow recirculation, keeping the fruit in suspension. We’ll continue this on and off until packaging.

Packaging

We package into 16oz brite (non-printed) cans with a label. We recirculate one final time for about an hour before the start of packaging. We then hook up our packaging line directly to the pump T-valve in case we see settling during packaging and need to stop and recirculate. As mentioned before, breakout is immensely slow with how thick the beer is, so FOB (Foam-On-Beer, a packaging term for the protective layer of beer foam that forms at the top of the can and helps to reduce oxidation) can be a pain. We tend to overfill to correct that problem. Our can weights are heavier than anything we packaging coming in between 515g and 525g. We check cans about every 20 cases to ensure they are properly mixed and carbonation is still holding properly until packaging is complete and beer is ready to head to our pubs!

Thoughts on Lactose and Creating a Balanced Beer

At Oakshire, we use lactose maybe once every two or three years when we make a traditional milk stout. Other than that, we manipulate our OG and FG with our fermentation profile to build the finishing gravity that we desire in our hazies, pastry stouts and smoothie sours. Especially with the smoothies, there is so much residual sugar from the massive fruit load, it feels excessive to use extra sugar. We also already use real marshmallow, which sounds and tastes better in the beer than using milk sugar, so we just keep it out!

Balance, on the other hand, is a trickier topic to tackle. At their essence, these beers are unbalanced; unabashedly bold and in your face. It’s a reason that certain groups of people scream up and down that these smoothies are not beers and shouldn’t be called so, and blah blah blah. I don’t agree with it, but I get it. That being said, there is a need to find balance within the adjuncts that you use. Each fruit needs to integrate with the next seamlessly. Too much Key Lime and you drive the acidity through the roof and overtake the beer; too much spice and you can instantly create a concoction that’s only drain pour worthy. We take it in the stride of cooking; each ingredient or addition needs to come together in a way that makes a beer that is that greater than the sum of its parts. It’s taking calculated balance to purposely create an unbalanced and loud product.

Fruit and Spice Integration into Overall Flavor Profile

Obviously, the biggest component and ultimate driving forces of these beers is the flavor combinations chosen and the additional adjuncts added to enhance the beers. Often, when you see breweries making smoothie sours, the ingredient lists sometimes look like they were just thrown at a wall to see what would stick, and often I think they are. We take a pretty methodical approach to coming up with new flavor and profiles. For the first few releases we focused on flavor profiles that we knew would work together, focusing specifically on fruits. We were really trying to recreate the smoothie experience. We look for jam forward berries that can work together, or known to work flavor combinations like Passionfruit, Orange and Guava (POG), or fruited lemonade flavors (Blackberry Lemonade).

Once we began to see success, we diverged into more ambitious flavor combinations incorporating adjuncts outside of fruit such as cinnamon, spices, graham cracker or coconut. At this point it needs to be decided how much of the adjuncts are needed in the beer. The goal is to create an experience representative of that stated on the label; too much of any adjunct and the beer can go completely sideways quickly. We always err on the side of caution with new adjunct amounts. It is also the reason that we often add those adjuncts with the marshmallow and vanilla beans and before the fruit. That way if we do not feel that the adjunct is coming through at our preferred level, we can add more in brite with the fruit. It makes it a win-win, especially when adding spices. Over time we’ve learned the proper amounts that fit our consumers’ palates to help with proper ingredient ordering so we don’t have to scramble to get more of any adjunct at the last minute, or put out a bunch of cash for ingredients that we aren’t using.

We have also built a sub-series of styles within the Theme label. Fans have certain ingredients they enjoy and we bring them back around with new fruit combinations. We have our Dreamsicle beers, which incorporate different fruit with tangerine or orange (think ice-pops), our Cinnamon Swirls (fruit and cinnamon combinations reflective of fruited swirl cakes) and the From The Bottom/From The Top series (two releases that pair together to “cuvee” or blend at home). We’re going to continue introducing new interpretations as well as some new additional series in the coming months!

Sometimes You Just Don’t Know What’s Going to Happen and That’s Okay

One of our first strange ingredient mishaps was with our Blueberry Coconut Dreamsicle. A few releases before we had done a Cherry Key Lime Pie which was finished on 200 lbs. of graham crackers. We had transferred the graham from secondary to the brite tank with the fruit, and packaged with no issues. It had little bits of graham in the can with the beer and people loved it, and we had zero issue with packaging because of the thickness. With the coconut we did not purposely try and transfer coconut bits to the brite, but some got through. We figured if we hadn’t had an issue yet with bits or floaties, then we should have a piece of cake packaging run. We were wildly wrong. Any chunks of desiccated coconut that made it to the cans caused absolutely terrible breakout like we had never seen before for these smoothie beers. We eventually had to stop and transfer the beer through mesh screens twice before we could return to packaging. Also, a ton of beer had been absorbed into the coconut, unknown to us. We finally were able to get the beer packaged after the filtering, but barely made our presold case count, and lost about 5bbls of beer in the process. That was a rough day, but set the course for how to plan and execute the use of certain types of new adjuncts moving forward.

There are some ingredients that there isn’t a lot of research or advice on using in beer, and sometimes you just have to wing it. We experienced that with our Mango Raspberry Cheesecake which integrated over 100# of New York-style No Bake Cheesecake mix. We weren’t going to add milk to the beer, so we ended up blending it up with water in our brink with a paint mixing attachment for our drill. It still made it super thick, almost the consistency of pudding, and using our brink we were able to slowly transfer the mixture to the cone of our Uni-tank before transferring the beer and fruit in after it to hopefully mix everything up. The plan worked perfectly and helped turn the already smoothie-like consistency to that of melted cheesecake. Super thick and actually really awesome; that was until the cans refermented and we had to issue a voluntary recall in January of this year, which sucked for sure. However, before that happened, we thought the beer was fantastic and now have a whole line-up of cheesecake variants planned for the rest of the year.

Oakshire Brewing’s Dan Russo (center)

The Recall, Aftermath and Path Forward

We began receiving word about a week after the packaging and subsequent release of the Mango/Raspberry Cheesecake Smoothie. A slow stream of emails started arriving through the beginning of the weekend that began picking up steam into Sunday night and through Monday morning. The story was all the same, it did not matter if the cans were stored in a cold fridge; when customers were going to open them, the beer was erupting out like a volcano and covering people’s kitchens in pink cheesecake beer. That Monday afternoon we convened and made the decision to voluntarily recall the beer. As every can was sold via online presale, we had an email contact list for every person that purchased that flavor and were able to quickly reach out and let them know that we were offering a refund or credit for future purchases, and instructions on how to safely dispose of any remaining cans. We also sent out a press release to beer blogs, knowing many of these beers were being traded around the country, with the same instructions.

The overall response from all the customers was appreciation that we had recognized the situation and took steps to rectify and reimburse for the lost beer, with a little side disappointment that they couldn’t drink the beer. Many reached out to let us know that other breweries who specialize in these types of beers have never offered a refund, or in some cases even an acknowledgement that the cans were exploding days after purchase. It garnered us a nice push of good will to our regulars and new smoothie sour fans alike. Our next release was only three weeks later and we nearly sold out of the 240 cases available the first day of the presale. We’ve realized from past quality issues that it is important to be forthcoming and honest with our consumers and that they will usually respond in the same way and in many cases frequent our pubs or consciously purchase our beer more often. It really ends up a win for everyone involved.

The biggest change that we have begun to implement is to our processes in production of the smoothie beers to ensure that we never see refermentation in the cans for any future release. It may have only been 1 issue out of 15 releases, but it was an eye-opening one to have. For the next release we reached out to our friends at Block 15 and they allowed us to borrow their bath pasteurizer. It is a significant added step in the process with multiple touch points for each case before even receiving a label; however, we feel it is necessary for the stability of our beer. Moving forward we are going to implement a two-step process that involves a sterile filtration of the beer between primary and secondary conditioning to remove yeast, as well as our own pasteurization unit. The goal is to have 100% assurance that cans will not re-ferment after purchase. We have performed sensory on cans that were pasteurized next to non-pasteurized cans with no discernable difference in look, smell or taste. We’re comfortable with how the beer turns out and can sleep at night knowing someone isn’t taking a smoothie shower in their kitchen!

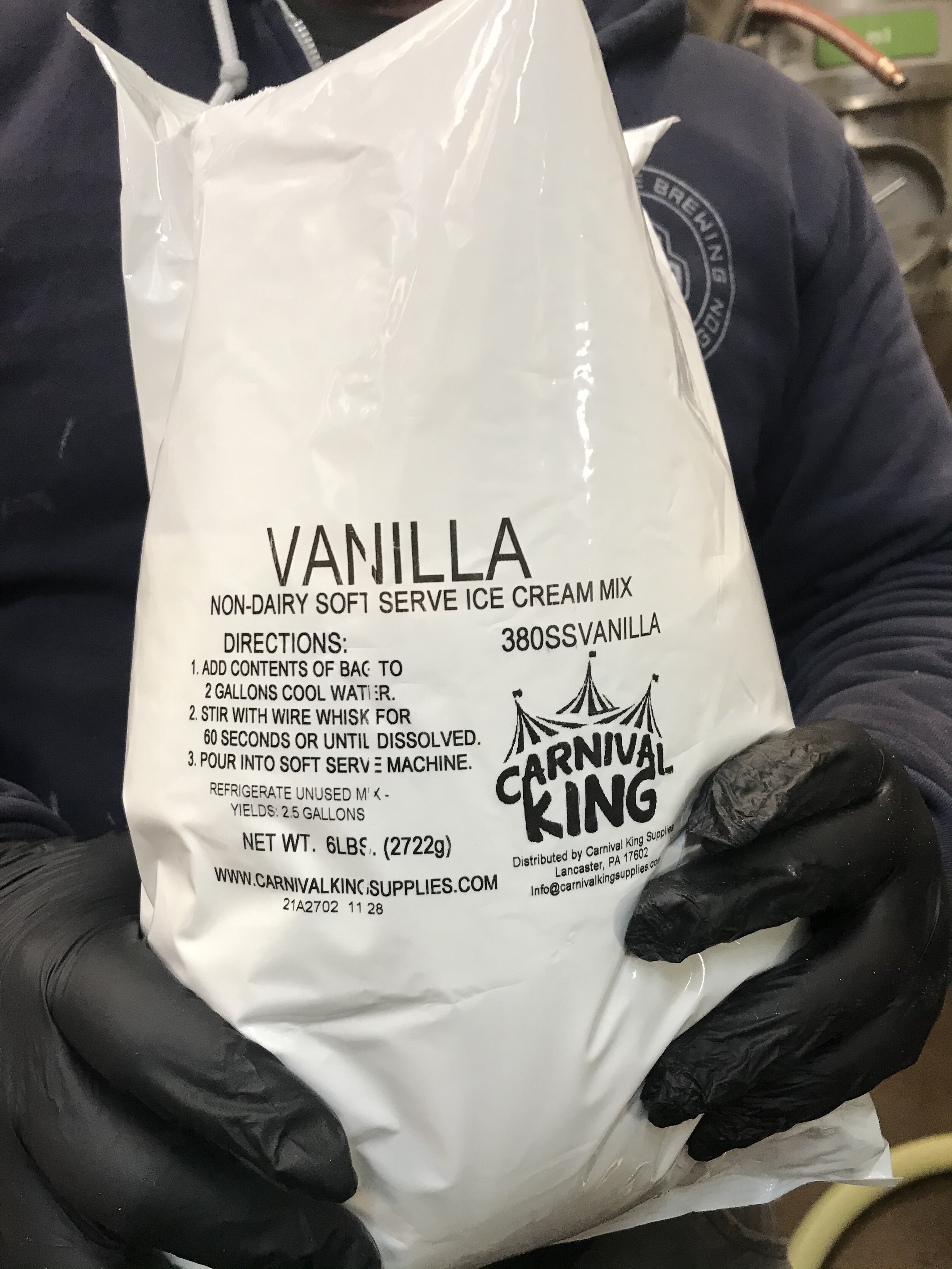

These smoothie sours can be as weird as they are wonderful, but the amount of creativity that can go into them is almost never ending. We have versions in the works over the next couple of months incorporating such ingredients as maple syrup, chocolate sauce, soft serve ice cream, cake batter, and rainbow sprinkles and that’s only through quarter 2. If you told me a year ago that I would be planning over 40 versions of these beers for the 2021 brew year I would have called you a crazy person; but here we are, and we’re having a blast doing it!

If you ever have any questions feel free to reach out to dan@oakbrew.com and I’ll hopefully be able to get you some answers!

Cheers!

Smoothie Breweries to Check Out:

Claim 52 (Eugene OR) THICC series

Vegan smoothie beers incorporating tons of fruit, and other delicious adjuncts such as graham cracker, and vanilla. Also check out their STUFFED smoothie series for more dessert like offerings.

Urban South - HTX (Houston, TX) SPILLED series

These guys get wild; incorporating everything from candy, to exotic fruits, to white chocolate, pralines and coconut, while keep each one delicious!

The Veil (Richmond, VA) Tastee series

Some of the originial smoothie sours that incorporate lactose. Theirs a reason people seek these out, because they are delicious.

Burley Oak (Berlin, MD) J.R.E.A.M.

My first encounter with cheesecake in a smoothie sour and it did not disappoint. Tons of wild ingredients and definitely pushing the bounds of what people can consider putting in beer.

Drekker Brewing (Fargo, ND) Braaaaaaaains

Super solid smoothies that you can find throughout the PACNW at highend bottle shops, making it easier to track down then some of the others on the list that are only sold from the brewery's taproom. Well worth seeking out.

Kings Brewing (Rancho Cucamonga, CA) Fros'e

These guys absolutely rip out smoothie beers, and do an absolutely killer job. They don't shy away from new and intersting ingredient and flavor profiles, but also just slay it with good old fruit bomb combos.

The Brewing Projekt (Eau Claire, WI) Puft Tart

These guys are making their way around the NW with their Puff Tart and Puff Tart XL series. Slammed with fruit and vanilla. Well worth checking out if you catch them on the shelf at your favorite bottle shop.

RAR Brewing (Cambridge, MD) Out of Order

The second cheesecake sour I had and solidified that I was going to take my chance at making one myself. This crew takes it to the extreme with no ingredient out of play. I've seen everything from Blue Raspberry snow cone syrup, to cotton candy and pastry cream incorporated and done well!